Density is a characteristic property of a substance. Each substance has a density that differs from the densities of other substances. A rock with a high density is “heavy”, and will always sink in water, which has a lower density. Similarly, the density of the human body is only 1.02g/cm3, while the Dead Sea has a density as high as 1.3g/cm3 – this explains why a human being can float on the Dead Sea.

At Ohaus, they help to determine the density of various substances for the purpose of testing the quality of finished goods, and for research purposes using the Ohaus Adventurer AX Analytical Balance.

So what is the relationship between density and production? In production, determining density is essential to identify materials and their components, and determine the quality of materials etc. in order to monitor production, and control quality. Below you will read more about two instances where the Density Determination mode on the Adventurer analytical balance was used.

Density Determination in Glass Production

Glass is easy to shape. It can be formed into various shapes, thickness and even transparency, in accordance with different processing technologies. There are many different types of glass based on their chemical composition. Glass composition refers to various oxides and their weight proportions within the glass. In production, if the glass composition fluctuates and exceeds a certain range of fluctuation, it will not only cause changes in the properties of the glass but will also affect the quality of the end product. Therefore, whether or not the glass composition is stable is one of the most important factors that affect the production of glass.

In glass production, two methods are commonly used to detect the stability of the glass composition: Chemical Analysis and Density Determination. The latter is much easier and more efficient.

In glass production, two methods are commonly used to detect the stability of the glass composition: Chemical Analysis and Density Determination. The latter is much easier and more efficient.

Glass density is sensitive to the proportions of oxides that make up the glass composition. The glass density fluctuates once the proportion deviates from the normally controlled range.

For example, the moisture content of quartz sand is easy to change and often fluctuates within 3 to 10% (mass fraction), which can result in a glass density change of 0.01g/cm3. Therefore, the manufacturer determines the fluctuation of the glass composition by regularly measuring the density of the glass. In case of the density of glass fluctuates, the manufacturer can adjust the proportion of each oxide in the glass in based on characteristic properties of the product in order to maintain the stability of the density, as well as control the production status.

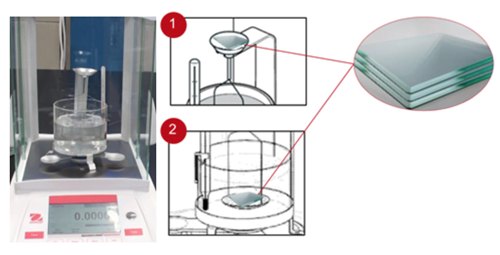

For this purpose, Ohaus performed Density Determination using some glass samples.

A glass factory in Zhejiang provided three pieces of glass samples for density determination. Samples are numbered in order of production time. They used the Ohaus Adventurer AX Analytical Balance since accuracy to 0.0001g/cm3 is required.

The density is determined by weighing the glass sample in air, and then in water. One thing to note is that temperature has a great effect on water and causes density changes, which is apparent in the third decimal place of the result. To obtain accurate results, it is highly recommended to measure the actual water temperature using a precision thermometer before every measurement. In addition, it’s essential to remove the water droplets on the beaker, holder or tweezers to avoid weight increase, which can result in inaccurate results.

Density Determination in Cough Syrup Production

A Chinese pharmaceutical company in Yunnan sought to measure the density of children’s cough syrup by internal quality personnel before leaving the factory. Cough syrup is a thick, gluey fluid, with sucrose and flavouring agents added to reduce bitterness and other unpleasant tastes. However, excessive sucrose content in cough syrup leads to high sweetness and thickness, making it problematic for children to swallow, therefore requiring mixing with warm water. Meanwhile, for pharmaceutical syrup, sucrose content should not be less than 45 (g/ml), which is stipulated in <0116 Syrups> (general requirements for preparations according to Chinese Pharmacopeia 2015 edition.) Thus, an appropriate sucrose content that’s neither too high nor too low is vital.

Typically, the syrup’s density becomes higher with increasing sucrose content. Based on this, we can find out the association between density of cough syrup and taste by repeatedly measuring the density, thus developing a cough syrup more palatable for children, as well as meeting the requirements of “Chinese Pharmacopoeia.”

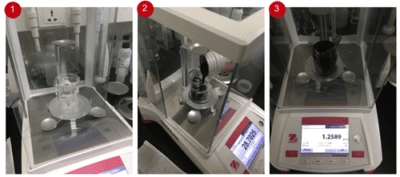

The company provided three bottles of cough syrup with different viscosities. Ohaus conducted the density determination with the aid of an Adventurer AX analytical balance. The density of cough syrup was determined by weighing a sinker first in air, and then in the cough syrup. It is important to immerse the sinker in the cough syrup so that the buoyancy force on the sinker is constant. If the cough syrup is too thick, they could gently press the sinker to keep it submerged. Additionally, they mixed the cough syrup with a stirring rod to dislodge any air bubbles before measurement. A bubble with a diameter of 1 mm causes a buoyancy of 0.5 mg, whereas one of diameter 2 mm results in buoyancy as high as 4 mg.

Why Choose an Ohaus Balance for Density Determination?

First, a built-in application and a density kit allows the Ohaus balance to meet the needs of density determination, especially when it comes to the Adventurer AX series. The colour touchscreen offers easy and fast operation, guiding users through every step of the operation process.

The balance software includes a built-in reference density table for water at temperatures between 10° C and 30° C. It calculates water density based on the water temperature value entered. Once the necessary weights have been determined, the density of the sample is displayed in g/cm3 on the application screen. Users can print out a detailed report with weight in air, in liquid, water temperature, density type and other related information.

Second, the internal quality personnel can quickly determine the density results by using an Ohaus Adventurer balance and thus adjust the recipes and formulas, saving users time and money by avoiding third-party services.

Learn more about the Ohaus Adventurer AX Analytical Balance Range

This blog was originally posted on Ohaus’ website and is reproduced with permission.