Understanding and complying with European Pharmacopoeia Chapter 2.1.7: Balances for Analytical Purposes

If your role involves the quality control of medicinal products and your company exports products into the EU, the new requirements stipulated in the European Pharmacopoeia Chapter 2.1.7 (or (Ph.Eur. Chapter 2.1.7) apply and are now in force. We look at the introduction certain measures that must be carried out periodically to optimise the performance of analytical balances.

Expert opinions: How IIoT technologies in weighing are addressing today’s production challenges

With ongoing reports of labour shortages and the rising costs of raw materials hitting production lines cross-industry, access to data via IIoT (Industrial Internet of Things) technologies offer invaluable insight to help manufacturers automate and drive efficiencies. As we celebrate our 50th anniversary and look to the future, Simon Hyde, Senior Engineer, explains how IIoT-enabled data capture and analysis are revolutionising traditional weighing processes and their role in addressing today’s manufacturing challenges.

Closing the gaps in weighing data for continuous improvement

A recent report conducted by LNS Research highlights the criticality of data for continuous improvement in production. For data to support positive change, it must be ‘highly organised and readily available to produce the desired results’1. How weighing data is collected, shared, and analysed can support this process. We look at potential gaps in this end-to-end process and the weighing solutions that can help you uncover crucial data to drive continuous improvement.

Enhance Overall Equipment Effectiveness (OEE) through weighing best practices

With equipment failures costing manufacturers circa £186,000 per hour1, one key solution to the mounting challenge is to evaluate and mitigate any weaknesses originating from critical production-line assets to reduce downtime and cost. Using the productivity framework of Overall Equipment Effectiveness (OEE), we highlight how weighing best practices can be implemented to improve availability, performance and quality loss to significantly enhance efficiencies along your up and downstream weighing processes.

Super-deduction tax break: A helping hand for your weighing investments

With the announcement of a £25 billion super-deduction tax break in the last budget, organisations will be able to claim 130% tax relief on spending against capital equipment. Designed to fuel business growth, we look at how the savings are applied and how it can provide welcome financial support for your weighing investments.

Expert opinions: The cost of human error and the role of weighing processes and technology

From misreading of results, recording results incorrectly, to a momentary lapse of attention, human error in manufacturing is so widespread that it is the cause of 80% of failures and defects1, 23% of unplanned downtime2 and can account for almost 11% of product wastage3. We asked our team of regional weighing experts to highlight the impact of human error and how processes and technology can help to mitigate risks.

Equipment failure: Proactive measures to prevent disruptive downtime

A study by Vanson Bourne found that 70% of businesses were not aware of when their equipment was due for maintenance, an upgrade, or replacement. Furthermore, 82% of those companies suffered at least one incident of unexpected downtime resulting in the inability to deliver services to customers, loss of production time, and business. With the risk of such damaging outcomes, we will look at preventative measures to help you safeguard your weighing equipment and your organisation.

Expert opinions: How calibrations provide measurement confidence

What role do calibrations play in helping you achieve measurement confidence and avoid the detrimental impact of inaccuracies? We put some FAQs to Mike Glew, Quality Manager at Northern Balance for his perspective on how data obtained from calibration tests help to identify risks and safeguard your critical weighing processes.

Traceable and UKAS calibrations – how do I choose the right option?

When requesting a calibration service, you may be offered a traceable or UKAS calibration, but which is the right option for your needs? There are fundamental differences that could impact on compliance and successful trading if an unsuitable calibration is performed. We highlight the key features of traceable and UKAS to help you choose the right calibration option for your operations.

Factors for determining calibration frequencies

If you work to ISO 9001: 2015 and/ or ISO 17025:2017 standards, it’s imperative that you establish a calibration programme that ensures the validity of the results given by your weighing equipment. While ISO standards outline the need for calibrations, no prescribed guidance is provided to determine calibration frequency. To safeguard the accuracy of your equipment, we look at key considerations to help you define the best frequency for your process, equipment and application.

Practical tips to prevent weighing downtime

Does your business rely on the performance of your weighing equipment to deliver high-quality products or services at optimal efficiency? The breakdown of weighing equipment can impact on your operations, which can result in lost revenue.

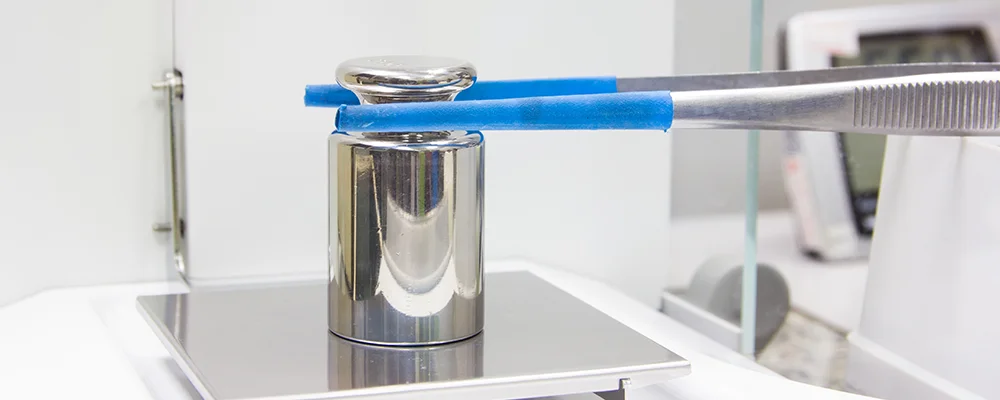

Understanding test weights and their impact on quality

As the accuracy of your weighing equipment’s measurements can fluctuate, routine checks with test weights can help spot any drifts and ensure that your equipment does not fall out of tolerance.

Limit infection through equipment cleaning

If cleaning is insufficient, this makes objects such as your weighing machinery highly susceptible to aiding infection. Stay safe and limit infection risk from your weighing equipment by reviewing our handy cleaning suggestions.

A Guide To Test Weights

Test weights are generally used for routine testing by the user of scales and balances outside of an external calibration regime (which is carried out on an annual basis by authorised service technicians such as Northern Balance)

Don’t harm your operations with inaccurate weighing

Inaccurate weighing can be detrimental to quality, efficiency and at worst, result in recalls and non-compliance investigations. With the risk of such detrimental effects, can you afford for weighing deviations and errors to occur?

Case Study: Density Determination with the Ohaus Adventurer Balance

Density is a characteristic property of a substance. Each substance has a density that differs from the densities of other substances. A rock with a high density is “heavy”, and will always sink in water, which has a lower density.

Weighing A Kilogram – For The Masses

It’s not often I tell people ‘this is an interesting fact about metrology’ without being laughed at. Well, November 2018 saw that change. On 16th November 2018, the International Bureau of Weights and Measures