Pipette service and calibration

Peace of mind for your liquid measurements

Pipettes play a crucial role in ensuring precise liquid volume transfers, but their performance can be affected by daily use, environmental conditions, and gradual wear, leading to inaccurate results and non-compliance. With such high stakes, regular pipette service and calibration are the most effective means to mitigate risks and prevent mechanical failure.

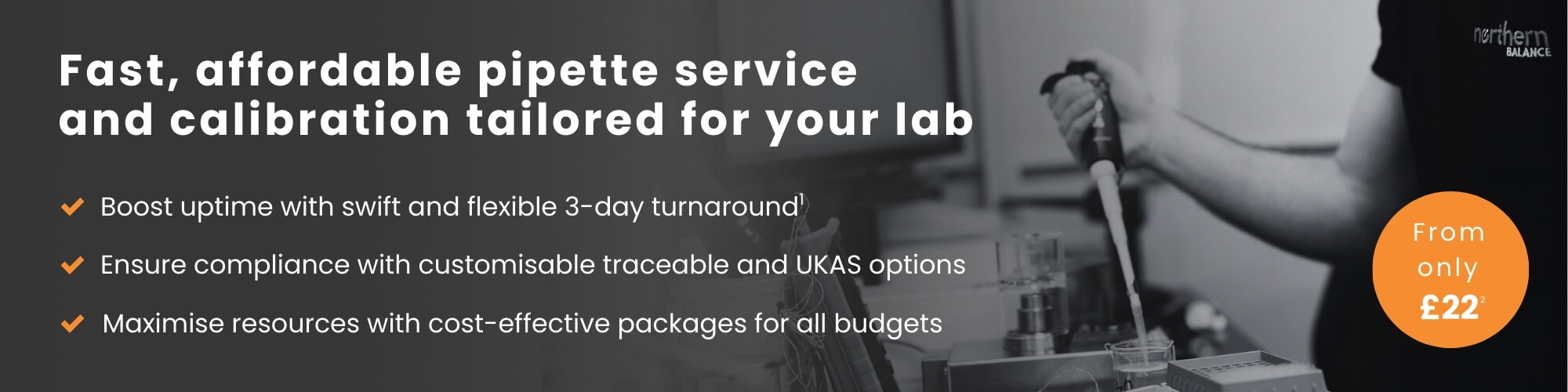

As an ISO 17025 accredited laboratory conforming to ISO 8655 International Standards, we provide fast, affordable, tailored pipette service and calibration for all makes and models to safeguard the accuracy and reliability of your liquid measurements.

Follow our simple three-step process to build your tailored pipette service and calibration solution today!

Step 1: Choose your uptime pipette solution

Step 2: Customise your calibration specification

| Measurement points | Volumes Points at which a calibration is performed against ISO 8655, a manufacturer’s or a custom specification | |||

|---|---|---|---|---|

| 1 test point | 2 test points | 3 test points | ||

| Readings Number of readings taken during a calibration to determine accuracy and precision | 4 | |||

| 5 | ||||

| 10 | ||||

Step 3: Select a package to suit your need and budget

| Features | Benefits | Basic From £222 | Enhanced From £272 | Complete From £452 |

|---|---|---|---|---|

| Calibrations | Mail in or on-site clinic service option | |||

| Traceable or UKAS ISO 17025 calibration | ||||

| ISO 8655/ manufacturer / custom specification | ||||

| As found results | ||||

| As returned results | ||||

| Servicing and adjustments | Visual and functionality inspection | |||

| External clean | ||||

| Internal clean | ||||

| Leak test | ||||

| Replacement consumables as needed4 | ||||

| Regreasing as needed | ||||

| Reporting | Label with next calibration due date | |||

| On-demand online certificate |

Quality and competence guaranteed

With over 150 years’ calibration expertise and our rigorous quality standards, we empower you to optimise pipette performance, measure confidently, and avoid the detrimental costs of inaccurate readings.

ISO 9001 certified, quality assurance is embedded throughout our operations. We have the competence to perform validated pipette service and calibrations and produce calibration certificates to globally recognised ISO standards. You can rest assured that we have the people, equipment, and systems in place to deliver internationally traceable pipette calibrations at all times.

View our certifications and accreditations:

ISO 9001 certification

UKAS ISO 17025 Accreditation Certificate

UKAS Accreditation Schedule

One-stop convenience for all pipettes

From manual to electronic, we service and calibrate all makes and models of single channel, multi-channel and repeater pipettes and more to offer you timesaving, one-stop convenience.

| Popular brands we calibrate and service | |

|---|---|

| Axygen | Onilab |

| Biohit | Sartorius |

| Biotix | Sigma-Aldrich |

| Brand | SLS Lab Basics |

| Clearline | SLS Lab Pro |

| Eppendorf | SLS Select |

| FinnPipette | Starlab |

| Gilson | Thermo Fisher Scientific |

| Heathrow Scientific | VWR |

Can’t see your pipette brand listed? Don’t worry, the brands aren’t exhaustive – our pipette service and calibration expertise covers all manufacturers!

1 Excluding potential repairs and postal delays.

2 Per pipette. Pricing varies depending on quantity and specific requirements.

3 Delivered by our family of ISO 17025 accredited partners for compliance and consistency across your supply chain.

4 Single channel pipettes only.

Get a free quote

Related resources

Expert opinions: How calibrations provide measurement confidence

What role do calibrations play in helping you achieve measurement confidence and avoid the detrimental impact of inaccuracies? We put some FAQs to Mike Glew, Quality Manager at Northern Balance for his perspective on how data obtained from calibration tests help to identify risks and safeguard your critical weighing processes.

Traceable and UKAS calibrations – how do I choose the right option?

When requesting a calibration service, you may be offered a traceable or UKAS calibration, but which is the right option for your needs? There are fundamental differences that could impact on compliance and successful trading if an unsuitable calibration is performed. We highlight the key features of traceable and UKAS to help you choose the right calibration option for your operations.

Factors for determining calibration frequencies

If you work to ISO 9001: 2015 and/ or ISO 17025:2017 standards, it’s imperative that you establish a calibration programme that ensures the validity of the results given by your weighing equipment. While ISO standards outline the need for calibrations, no prescribed guidance is provided to determine calibration frequency. To safeguard the accuracy of your equipment, we look at key considerations to help you define the best frequency for your process, equipment and application.