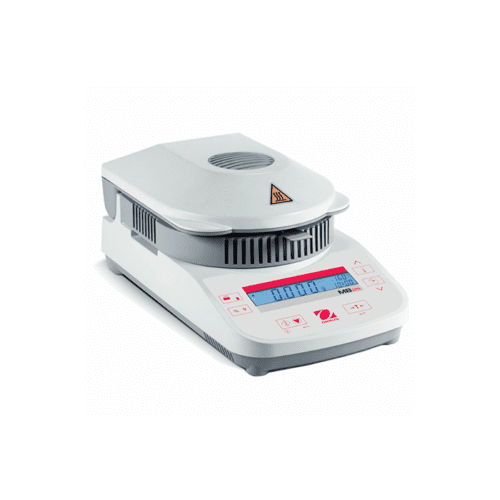

Used for analysing moisture content in samples, moisture balances (also known as moisture analysers) are suitable for use in laboratories, food production facilities, wastewater treatment plants.

Northern Balance supply a range of electronic moisture balances from manufacturers such as Ohaus, Sartorius, A&D and Adam.